Detail

DESCRIPTION

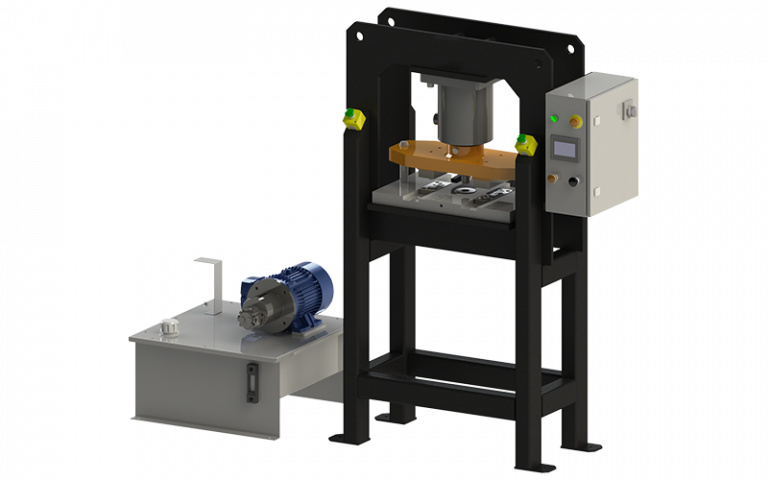

The press simultaneously performs the perforaion where the flange or valve holder is placed and the high relief engraving of themark on the upper cap.

BENEFITS AND CHARACTERISTICS

- High efficiency stamping and punching.

- Interchangeable dies.

- Only one operator per equipment.

- High strength steel.

- Continuous working hydraulic cylinder.

- Control valves.